kitty litter or HFB?

deejmemixx

Posts: 3,084 ✭✭

in Cigar 101

Ok so I just ordered my new wine cooler and the shelving units...so friggin excited!!! anywho, do I get 1 lbs of heartfelt beads or do I go with kitty litter....

I got a Koldfrond 28 bottle, with Edgestar 28 4 Drawer 2 shelf set Spanish Cedar set includes: 1 False front drawer, 3 double drawers & 2 shelves, just the pull notches but I upgraded the wood to Padauk wood. I ordered them through wineadors.com caaaaaaaaaaant wait.

I got a Koldfrond 28 bottle, with Edgestar 28 4 Drawer 2 shelf set Spanish Cedar set includes: 1 False front drawer, 3 double drawers & 2 shelves, just the pull notches but I upgraded the wood to Padauk wood. I ordered them through wineadors.com caaaaaaaaaaant wait.

0

Comments

-

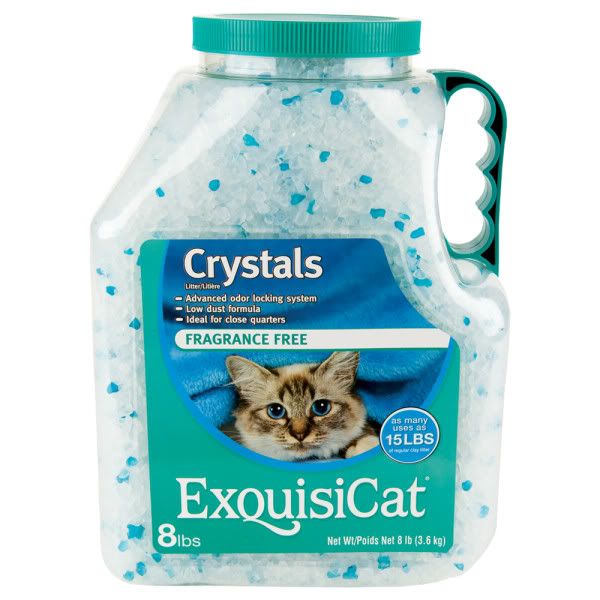

Silica is silica

SOME kitty litter is essentially the same as HF beads

TONS of threads on this subject here and other places

if money is no object, by all means, HF beads......

0 -

This will be fun.

HFB - $33.95 for 1 lb vs silica KL- less than $20.00 FOR 8 LBS!..........EIGHT POUNDS! Twenty BUCKS! Holy Crap!

Same stuff.

Yep, that was fun.0 -

thats my type of logic... and I know there are lots of threads...read them all, multiple times, just wanted to see if I got any other reactions.Bob Luken:This will be fun.

HFB - $33.95 for 1 lb vs silica KL- less than $20.00 FOR 8 LBS!..........EIGHT POUNDS! Twenty BUCKS! Holy Crap!

Same stuff.

Yep, that was fun.0 -

I'm wondering too if any hardcore HFB fans will show up. LOL (They are a dying breed.)

Congrats on the new wineador. I'd be excited too 0

0 -

I've been using KL for over 3 years now...32 humidors of different kinds can't be wrong..Tupperware, Wood, Cooleradors, etc. I've used HFB and they work great as well but the cost was something I couldn't afford. I still have half a bottle of KL from the 8 pound jug I bought 3 years ago...the stuff just works.0

-

What brand you use?Cigary:I've been using KL for over 3 years now...32 humidors of different kinds can't be wrong..Tupperware, Wood, Cooleradors, etc. I've used HFB and they work great as well but the cost was something I couldn't afford. I still have half a bottle of KL from the 8 pound jug I bought 3 years ago...the stuff just works.0 -

-

I do use KL but its not the same at all. HFB are two way control where KL really only releases humidity (unless you put it in dry without spritzing then it will absorb some). It ends at them both containing silica.0

-

what??Vision:I do use KL but its not the same at all. HFB are two way control where KL really only releases humidity (unless you put it in dry without spritzing then it will absorb some). It ends at them both containing silica.

wrong.........0 -

here's a little info on silica......from a botl who knows:

A lot of that is pure marketing speak and is largely just flat wrong and with no basis in science. Silica gel beads come in several varieties with the main three being nano-pore (type A), micro-pore (type and wide (or macro) pore (type C). Each type has specific characteristics which lend them to be suited for particular uses.

and wide (or macro) pore (type C). Each type has specific characteristics which lend them to be suited for particular uses.

Type A nano-pore beads are generally best suited to desiccant-only use. Type-A beads have a very narrow range of humidity response regardless of temp (within limits) or humidity (within limits) up to their capacity to absorb moisture. Since the appearance of the various types of silica gel beads is pretty much identical, an easy way to ID type A beads is to spray or soak them with water. Type A nano-pore beads will fracture (break into many pieces/turn to sand) in the presence of liquid water.

Type B and Type C are both suitable for humidity control and the level of humidity (the set point) is based on pre-conditioning and the essentially linear response curve of these bead types. Type B and Type C beads tend to adsorb (not absorb) moisture at high relative humidity levels and desorb as humidity levels fall. This response curve is why Type B and Type C beads are in fact the base products for humidity control in contained museum exhibit and gallery use. (Artsorb.) (See some response curves for the various types of silica gels in the charts at Broadchem* at Qingdao Broadchem Industrial Co., Ltd and WR Grace at W. R. Grace & Co. Enriching Lives, Everywhere.® - Adsorption on Silica Gels.) Beads are not "pre-set" as "pre-set" implies that beads will maintain one specific level of humidity up to the limits of adsorption (saturation) or desorbtion (dry.) Silica gel beads are instead "pre-conditioned" (which is to say they are "set" to a level of RH at a certain temperature by exposing them to the desired RH at the desired temp until they achieve equilibrium.)

Heartfelt beads are just plain silica gel type B or Type C beads. Nothing more. Nothing less. There is nothing magic about them except the price. Buy the cheapest Type B or Type C beads you can find and use those. The silica beads in some brands of cat litter** are suitable. (It isn't cat litter until your cat uses it. It's just silica gel.)

Sorry if I've stepped on any toes here, but this is an area I happen to know something about based on years of work for the archives at the Air War College at Maxwell AFB in Montgomery, AL. I had wondered about Heartfelt and their claims for a while. I have no idea if they believe what they are saying or if they just don't understand the science. Either way, their product is nothing special. Just over priced.

*The Broadchem charts are probably the more instructive. Suffice to say that these charts show that both Type B and Type C beads have the ability to adsorb more moisture at high levels of RH and less moisture at low levels of RH. Think about what that means and you will see that contra the marketing speak claim ("Humidification beads give off water vapor, as well as absorb it, to maintain a specific RH which is ideal for a cigars particular need. This is not the case with silica gel which can only absorb water then must be dried out after it is saturated"), Type B and Type C beads do in fact have the inherent ability to both adsorb and desorb. In fact, even Type A beads can both adsorb and desorb moisture, but the limited response curve of such nano-pore beads is not well suited for RH set-point stabilization so much as for drying.

**Crystal Clear Litter Pearls are generally Type B, Type C or some mixture of the two and are perfectly suited for the purpose of cigar humidor humidity stabilization and control.

0 -

Here is a little info on beads.....from a botl that knows

I've been messing around with RH beads and other humidifying media for the last month or two and came up with this RH beadstick idea among others... http://www.clubstogie.com/vb/showthread.php?t=138682 I struggled with whether or not I'd mess around with them so far as to offer them to the public, I was pretty content with just dropping them in bombs and so forth.

Dball mentioned that they were ideal for what he does in a lot of different ways, and that they'd be ideal in his traveling humi.

I can make up the beadsticks in any vitola (or at least get them close), but it's a lot of tedious handwork and my arthritis makes it a chore. It makes things slow, too.

Anyways... I ran tests on a lot of different medias with a lot of different additives.

The medias I use were Polyacrylamide (the gel like in drymistats) in two different sizes, four different grades of RH beads, two different silica gel "chip shaped" dessicants, and a type of bead called Molecular Beads. I steeped the different medias in a bunch of different solutions. The solutions I chose were off the shelf items that were food grade and safe for use around my cigars. I didn't want anything near my cigars that I wouldn't put in my mouth.

I used food grade propylene glycol,Magnesium chloride (salt), Sodium Nitrate (food preservative, it's in your beef jerky), Potassium Chloride (salt substitute for folks who can't use salt), and Sodium Chloride (table salt)

If you count up those items, there are 14 items and a huge number of combinations.

So I took to making up test subjects by combining salts and PG with all the different test medias. I also used multiple combinations of salts and pg to create different RH values. What I found was that I could tweak any of the medias to hold any RH value I wanted anywhere from 32% all the way up to 86%.

All I really wanted to know is how well any combination would work to control humidity in my humidor, and how they would work in my incubators, and other applications. The reason I chose to use all food grade and the very purest of medias is that for a lot of years I've provided incubators and humidity control systems to labs, colleges, hatcheries, The UN's Food and Agriculture Organization, and to poultry enthusiasts worldwide. I've invented a couple temperature control systems that are used all over the world in a number of different applications.

So I knew if I was to create something that was worthwhile, it'd have to work across the board. I spent a lot of time speaking to overseas manufacturers and the few major distributors of these products in the States.

What I found out, across the board, is that none of them had done the tests that I proposed. Dessicants (all the RH beads are exactly that) are generally used for drawing moisture out of enclosed areas. They are used widely in the shipping industry and in the electronics industry. You know those little packets you find in your beef jerky bags? I always thought they were Dessicant Packets. They're not. They're oxygen scavengers. They suck oxygen out of the bag to keep the jerky fresh.

Back on track... Some tests were an absolute failure and some worked extremely well. Rather than go into a metric ton of charts and test data, I worked out something of a rating system. I wanted to know how quickly the test subjects would pull humidity out of the air, and how well they would let humidity back into the air. It was pretty easy, actually. All I needed was a see-through box with a divider and a couple hygrometers. All the tests were done at one temperature, 70F. Equal amounts of media by weight were used, arranged to expose an equal surface area by square inch. Some products had a distinct advantage because their shape created a much larger surface area per area. Such as beads are round, gel is chunky, while solutions were flat and silica gel chips were flat sided. This factored in heavily, making different shapes a better choice for our application in humidors, as well as in incubators. I was concerned whether temperature would make a great difference, so I did a couple quick mockups at 60F and 80F. The difference in reactivity was negligable, so I was content to leave that alone. Another thing I found out that went right across the board was that any treatments I used with the media lessened their reactivity. If I added salt to beads, they reacted slower. If I added PG to beads (I could only do this with one grade of beads) it reacted slower. So I threw out the idea of adding anything to beads. I knew I could use these solutions to my advantage later, but I won't get into that yet.

What I wanted to do was to come up with a simple number that would give an easy means to gauge "how much of what" should I use to achieve the same results? I scored the least responsive product at 1.0 and the most responsive product at 10.0. It would also allow me a means to calculate expense quickly and easily.

Here follows the numbers I came up with... Grade 1 chips 1.0 Grade 2 Chips 1.3 Size 1 Poly Gel 4.0 Size 2 Poly Gel 3.6 Grade 1 Beads 2.0 Grade 2 Beads 5.0 Grade 3 Beads 6.1 Grade 4 Beads 6.6 Grade 1 MBeads 10.0

I also did quickie tests on four different popular bead products and one gel product that are used in conservatory applications (museums) and in our humidors. I found only one commonly used product scored very low, at 3.4. Three scored in the 6.0 to 6.5 range. There was one product that stood out at 7.4. Regardless of the score, all the consumer bead products I tested were an excellent value as indicated by cost per product efficiency ratio excepting the one gel product. It would be of equal value if it was priced at 25% to 40% of it's current cost. Arranging the gel differently to provide more surface area would increase it's value.

I did find out one thing that's been debated heavily. I tested the Kitty Litter that folks have gone on about. It takes a little over 3 times the amount of Kitty Litter to do the job of one volume of any of the bead products we currently use. One good thing about kitty litter is that it doesn't explode on contact with water. There's a reason why that is, but I'm not going into it because it's windy and very technical and boring. )The Molecular beads also do not explode when water hits them. Suffice to say that if you have three pounds of litter in your humi covering 3 square feet of floor space, it will do the job of one pound of the RH beads covering one one square foot of floor space. I don't have room in my humi or wine coolers for all those beads. I need to put cigars in there. I've heard a lot of argument about the "quality" of kitty litter beads possibly being lower than that of the other RH beads. I spoke to the manufacturer (who coincidentally makes all the grades I used) and they are manufactured to identical specifications.

Another thing I found... I found exactly ONE manufacturer of silica based beads in the world. That was after chasing down each product through MSDS sheets and product ingredients. If there are any others I'd like to know about them. I also found only one manufacturer of the MRHbeads. They offer two different labratory grades of those beads, I choose the product with the smallest pores.

One last thing I found... Once RHbeads have been in direct contact with water, explode and turn to powder, it's ability to perform in these tests decreased dramatically. It's because as a powder it's lost a great proportion of it's effective surface area. Although it still worked as intended, it lost a great deal of it's abilty to react quickly to humidity changes in it's environment, and lost a large amount of it's ability to hold water that can be made available to it's surrounding atmosphere, meaning it would not last nearly as long without needing to be reconditioned. As a result of these circumstances, powdered beads faired very poorly so I threw those results out of my test data. Those tests results do say one thing to me. NEVER pour water directly on beads. It severely diminishes their capabilities. Use a conditioning bag or simply set a tray of water near the beads and be patient. It will prolong the life of your beads dramatically and increase their value exponentially.

In summary... I have concepted about a dozen different products based on my tests. I'm most excited about offering them in the lab and hatchery industries because I'm at home there and have been for almost 15 years. The outlet is already there and I can help a lot of folks in a lot of different applications. The cigar keeping addiction is new to me and it'll take awhile for me to apply what I've learned to keeping humidity in my humi and my wine coolers. I've guinea pigged my two wine coolers from the start and have tried a number of different things in my humi, all with varying results. I've already developed a system of sorts that employs the RHbeads in stretch polyester fabric that works real well. I've created conditioning bags using polygel and a 51/49 PG solution for conditioning beadsticks at 70%. That combination yields a rock solid 69% RH in my far less than stellar leaky humidor.

In the next few days I will finish creating a 65% RH system. I've narrowed down what I'm going to use, as well. I'll be using salts, PG Solution, polygel, distilled water, RHbeads and MHbeads. All the products are Food Grade or intrinsically safe to be used around my cigars. I'm incredibly **** about those sorts of things.

My main problem is that I only have so much time to devote to this as I'm busy working on lab and hatchery systems right now. It's the height of hatching season and soon the colleges and labs will be heavily involved in West Nile Virus testing, meaning just about every incubator in the United States will be fired up and struggling with humidity control. I feel it's important to devote my efforts to those areas first, although I admit I'm having a lot more fun playing with my cigars. I can prepare humidor applications far more quickly because they are far less technically demanding. In the coming weeks, I'll be able to offer some of the RHbeadsticks and MHbeadsticks, along with their corresponding conditioning bags. I've already sent some out to some of the Gorillas here and I have some more prototypes made that I'll be sending out shortly. I should be able to offer all the different systems at a very competitive prices at first, only getting better later once I can scope the volume. I may just bag the whole thing, because I don't know that I have the time to devote to all of this. I'm pretty much on the fence right now. I do have the support of the leading dessicant distributor in the States, and they are excited about seeing my results, and are excited to see the tools I invent for conditioning bead products. So I'm just going to take it a day at a time and see what happens. I sure hope I didn't bore you all to tears!!! Scott

This was taken off a different site so I do need to note that this is not my writings. Thank you to Scott who did this research.0 -

KingoftheCove:

what??Vision:I do use KL but its not the same at all. HFB are two way control where KL really only releases humidity (unless you put it in dry without spritzing then it will absorb some). It ends at them both containing silica.

wrong.........

So what is the EXACT RH KL is designed to regulate to? 60%? 64%? 70%? I know that even with an over saturation HFB will regulate to 70% +- 2%0 -

Kitty Litter is a one way media...that means you "choose" at what RH you want and it's about how you introduce KL into your humidor. Here is the classic method of doing this. 1. Depending on how big your humidor is let's say you have one that is a 150 count size...this means you use KL as you would beads...except you don't put any DW on the KL yet. 2. Wait for a few hours ( 4-6 ) and see where your RH is...usually when presented dry it's around 58-61%. 3. Take a small bottle of Distilled water and spritz it over the KL ( about 2-3 spritzes should do ) and wait another few hours and check your RH...it should move up about 2-3% ) Here is how KL works...you want to expose as much KL as possible in the container that you choose to put in your humidor...the more exposure the better ) 4. When you recheck your RH again you will know that 2 or 3 spritzes of DW will give you a value of how ever much your RH rises. Once you get to YOUR choice of RH then you stop spritzing. It's pretty simple and once you get your RH dialed in it's just rechecking every 2 weeks to ensure that your RH is where you like it....that's it!0

-

Cigary:Kitty Litter is a one way media...that means you "choose" at what RH you want and it's about how you introduce KL into your humidor. Here is the classic method of doing this. 1. Depending on how big your humidor is let's say you have one that is a 150 count size...this means you use KL as you would beads...except you don't put any DW on the KL yet. 2. Wait for a few hours ( 4-6 ) and see where your RH is...usually when presented dry it's around 58-61%. 3. Take a small bottle of Distilled water and spritz it over the KL ( about 2-3 spritzes should do ) and wait another few hours and check your RH...it should move up about 2-3% ) Here is how KL works...you want to expose as much KL as possible in the container that you choose to put in your humidor...the more exposure the better ) 4. When you recheck your RH again you will know that 2 or 3 spritzes of DW will give you a value of how ever much your RH rises. Once you get to YOUR choice of RH then you stop spritzing. It's pretty simple and once you get your RH dialed in it's just rechecking every 2 weeks to ensure that your RH is where you like it....that's it!

Ive been using KL for a while now. I trained my at 67%-69% (Depending on spritz) I like it but I am just looking for an easier way and two way control.0 -

Beads are a 2 way but you probably already know the cost. Not sure how easier you can get with KL as I have 32 humidors of varying sizes and cooleradors as well. I just check the hygros once every few weeks which takes about 5 minutes and if the KL needs a spritz then I give it a couple of shots and I'm done.0

-

Vision:KingoftheCove:

what??Vision:I do use KL but its not the same at all. HFB are two way control where KL really only releases humidity (unless you put it in dry without spritzing then it will absorb some). It ends at them both containing silica.

wrong.........

So what is the EXACT RH KL is designed to regulate to? 60%? 64%? 70%? I know that even with an over saturation HFB will regulate to 70% +- 2%

Bump0 -

Bump for Bob Luken --- lots of info on first page.

* I have a new address as of 3/24/18 *0 -

There always seems to be a debate when using KL...it's one of the simplest forms of humidification. KL is not designed to have a certain RH...it's a media that you use to achieve whatever RH that you want. KL is as was said a one way media unlike beads that are a two way...it takes in RH and gives off in order to achieve a certain RH...beads come in different RH numbers that will achieve 62 or 65 or 70. KL takes in RH so it's up to the person to train the crystals of the KL at what percentage they want by a series of spritzing distilled water over the surface area of the KL. It requires time and a little math...you wait about 6 to 8 hours to see the change of upward RH by the number of spritzes you make...example.....dry KL is at 60% and you spritz the KL 3 times...wait another 6 or 8 hours and see how much the RH has moved up..usually it's about 3%...so now you have your equation that 3 spritzes equals 3% movement upwards. If you want your humidor at 66% then you spritz 3 more times.Vision:Vision:KingoftheCove:

what??Vision:I do use KL but its not the same at all. HFB are two way control where KL really only releases humidity (unless you put it in dry without spritzing then it will absorb some). It ends at them both containing silica.

wrong.........

So what is the EXACT RH KL is designed to regulate to? 60%? 64%? 70%? I know that even with an over saturation HFB will regulate to 70% +- 2%

Bump0 -

Great info.... but I have a question.

OK So there are HF beads, KL, Gel, etc.

My question is What is in Boveda packs? Is it one way or two way? How does it compare to beads or KL or ??0 -

This must be one of the best posts i've ever read on here..... Lots of info.... Just to leave you guys with my 2 cents i use HFB... KL may be great but i cannot get the image of KL being used for cats to piss and *** on... And because of this i cannot place it in my humidors....0

-

Well I've found a new bead too use...it's more them kl and less then hfb. Mixed in combo with my boveda packs well I'm happy and crap 4 boveda and a small thing of beads keep my 48qt at a steady 67rh. As for this ugh debate I'm with vision! I've done a crap load of experimenting and well as you can see I've gone too something I can't beat without pulling my hair outMoney can't buy taste0

-

I was at the point you are now about 4 years ago and the more I read the more curious I became. I started with my own experiment of one humidor that housed 150 cigars that was always giving me grief as to maintaining RH at 65%...so I started with the KL and put a half pound in the humidor where I just let it sit for 8 hours to see where my RH was....it was at 60% so I spritzed the KL about 3 full squirts and waited another 6 hours and it moved up to 63%...that gave me my magic number of how to get to 65/66 RH so I spritzed it one more time with 3 squirts and voila'..within 6 hours it was spot on at 66% and stayed there for almost 2 months before it went down by one percent and then I spritzed it with one squirt......checked it at 6 hours and it was at 67%. I tried another humidor with the same results...easy, accurate and I was now a firm believer in that I had 20 humidors at that time and every single one that I converted over to was just as easy. Once you get past the notion of what cats do with KL then you can safely know it's ok to use....there are museum curators who use KL for their priceless works of art to keep them at a constant RH they need to protect those works of art...if they can do it for those then I think it's more than safe to use as a media to protect cigars.edelrionyc:This must be one of the best posts i've ever read on here..... Lots of info.... Just to leave you guys with my 2 cents i use HFB... KL may be great but i cannot get the image of KL being used for cats to piss and *** on... And because of this i cannot place it in my humidors....0 -

im gonna have to disagree with museum curators using kl...first all museums have vaults that are temperature and humidity controlled. This doesn't mean putting things in a small space for safe keeping. If a museum relied on kl for some of the stuff it's for extremely short term! And your sticks aren't really a short term thing. If they were well you probably wouldn't have a huge humiCigary:

I was at the point you are now about 4 years ago and the more I read the more curious I became. I started with my own experiment of one humidor that housed 150 cigars that was always giving me grief as to maintaining RH at 65%...so I started with the KL and put a half pound in the humidor where I just let it sit for 8 hours to see where my RH was....it was at 60% so I spritzed the KL about 3 full squirts and waited another 6 hours and it moved up to 63%...that gave me my magic number of how to get to 65/66 RH so I spritzed it one more time with 3 squirts and voila'..within 6 hours it was spot on at 66% and stayed there for almost 2 months before it went down by one percent and then I spritzed it with one squirt......checked it at 6 hours and it was at 67%. I tried another humidor with the same results...easy, accurate and I was now a firm believer in that I had 20 humidors at that time and every single one that I converted over to was just as easy. Once you get past the notion of what cats do with KL then you can safely know it's ok to use....there are museum curators who use KL for their priceless works of art to keep them at a constant RH they need to protect those works of art...if they can do it for those then I think it's more than safe to use as a media to protect cigars.edelrionyc:This must be one of the best posts i've ever read on here..... Lots of info.... Just to leave you guys with my 2 cents i use HFB... KL may be great but i cannot get the image of KL being used for cats to piss and *** on... And because of this i cannot place it in my humidors....Money can't buy taste0 -

First of all you can disagree but that doesn't mean you're right. I know at least 3 curators who use the stuff...not as a first line defense for RH but as additional defense for items they tell me it's used for....regardless of short or long term. Your next query about length of term....KL is used for short or long term and I've heard too many debates from those who still want to condemn the merits of KL ...basically because cats pee on it and it becomes anathema to a host of many who do not really know the merits of what it is and what it can do. I do say this with respect and not wanting to enter the KL debate once again...if I've been in one I've been in them for at least a couple of dozen times. People just can't get their heads around it being a humidifier...just like I did until it proved itself beyond a shadow of a doubt. Pushing an agenda based on non factual data does not negate what it does....and if I didn't know the people personally who use the product I surely wouldn't go out on a limb just to debate the subject matter....I may be retired but that doesn't mean I want to stir up things just to stir the waters....I only want to suggest that KL is just as viable a media as others are...respectfully spoken.0

-

I don't think most people have a issue with cats peeing on it it's more about the space it takes up. In my experiments silica really only has expelled moisture...the only thing that has changed is the rate it is expelledMoney can't buy taste0

-

This revived thread is giving me a headache,................... I know KL works for me but I still don't get it. Maybe I'm just dense, but how come KL is considered "one way" humidification medium and HF beads are considered two way? I know some of you have tried to explain the difference but I'm still not gettin' it. Even though there are differences, (Like you apparently need more KL than HF beads to do the same job) don't they function in the exact same way?0

-

There are one way medias and 2 way medias...2 way medias give off and take in to which beads do very well. They are very popular but cost more. Kitty Litter is indeed a one way media that takes in and holds onto the RH until they dry off...that simple. No need to take a science class to figure it out...it just works.0

-

You call it a one way but, (to me) you describe it like it's a two way. You said it "takes in and holds onto the RH until they dry off." Sounds to me like you're saying that first it absorbs RH, (moisture). OK that's one way. But then you describe it as "drying off". Isn't that the same as saying it releases moisture? In that case, it's now going the other way, the second way,....................it's a two way, right?Cigary:There are one way medias and 2 way medias...2 way medias give off and take in to which beads do very well. They are very popular but cost more. Kitty Litter is indeed a one way media that takes in and holds onto the RH until they dry off...that simple. No need to take a science class to figure it out...it just works.

I'm not trying to be a pain in the azz. I just don't understand how it could be a one way. Seems like it's a two way situation to me.

0 -

Bob Luken:

You call it a one way but, (to me) you describe it like it's a two way. You said it "takes in and holds onto the RH until they dry off." Sounds to me like you're saying that first it absorbs RH, (moisture). OK that's one way. But then you describe it as "drying off". Isn't that the same as saying it releases moisture? In that case, it's now going the other way, the second way,....................it's a two way, right?Cigary:There are one way medias and 2 way medias...2 way medias give off and take in to which beads do very well. They are very popular but cost more. Kitty Litter is indeed a one way media that takes in and holds onto the RH until they dry off...that simple. No need to take a science class to figure it out...it just works.

I'm not trying to be a pain in the azz. I just don't understand how it could be a one way. Seems like it's a two way situation to me.

Dry KL will not regulate to a specific RH. It might absorb some moisture but not much. Beads will absorb to a specific RH. I have 65% and they will pull RH/Moisture until they are "full". If you put 65% beads in a 90% RH environment it doesnt mean they will magically drop the RH to 65%. They will absorb only up to the specific RH they are designed to absorb. If it gets too dry they will release that stored moisture back into the enviroment. I intentionally SOAKED 3/4 of my beads and its still solid at 70%. The other 1/4 can not pull any more moisture from the over saturated ones...... I did soak the media bag they are in too.... which doesnt help the 5% difference.... out of the bags they are at 67%0 -

I can assume HF beads and KL are different. But what I want to know is, if they are different, WHY they are different? What factual fundamental physical difference is there?0